What does Regulation 22 compliance mean?

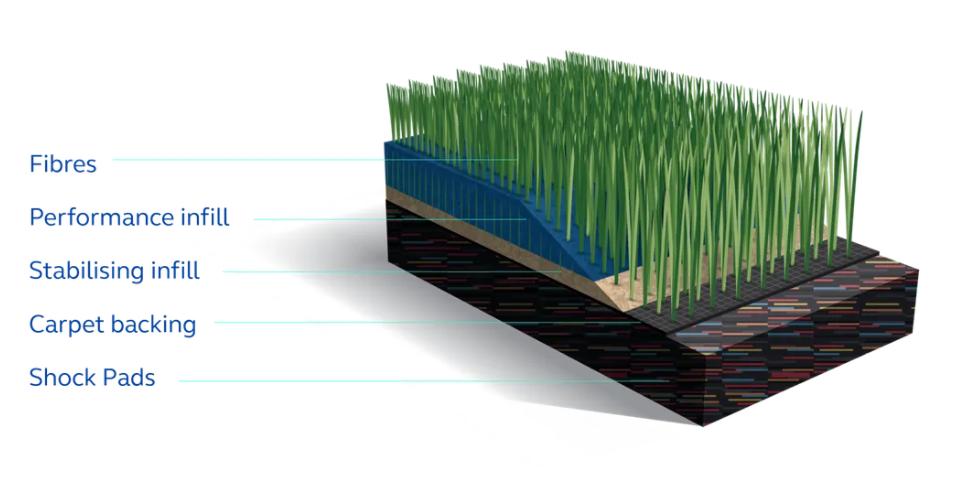

Regulation 22 applies to, traditionally, four elements of a surface (collectively referred to as a “product”). They are:

- Carpet (backing with fibres)

- Stabilising infill (traditionally sand inserted between the fibres)

- Performance infill (synthetic or natural granulate inserted on top of the stabilizing infill and between the fibres)

- Shock pad (an elastic layer installed under the carpet).

The combination of each is balanced by the manufacturer to ensure the field performs as expected. Adjusting one of the elements can materially affect this performance and results in it being considered as a different product.

Regulation 22 does not require that all four elements are in place, but there are no currently compliant surfaces that do not include all four. The aim of Regulation 22 is to encourage innovation in rugby turf, while ensuring that the surface performs as expected.

The use of a shock pad for new fields is critical to ensure that the HIC requirements (the HIC test mimics head impact on the surface) are met. There are additional benefits to using a shock pad and more information can be found at https://www.world.rugby/the-game/player-welfare/surfaces/shock-pads.

A Regulation 22 compliant field has undergone the following process:

- Product lab tested and shown to meet the performance requirements

- Product installed on the field

- Field tested against the performance requirements.

Once successfully tested, a field remains compliant for two years from the test date and must be retested to continue to be used for rugby. Member Unions are free to request more frequent testing of artificial turf fields and for some competitions, World Rugby insist on annual testing.

To reduce the impact on colour blind people, World Rugby strongly recommend that red lines are not used on a rugby field. This is most likely to affect multi-sport venues with multiple lines.